3D Scanning Services

For Modern

Reverse Engineering.

Modern Reverse Engineering Services

From Days to Minutes

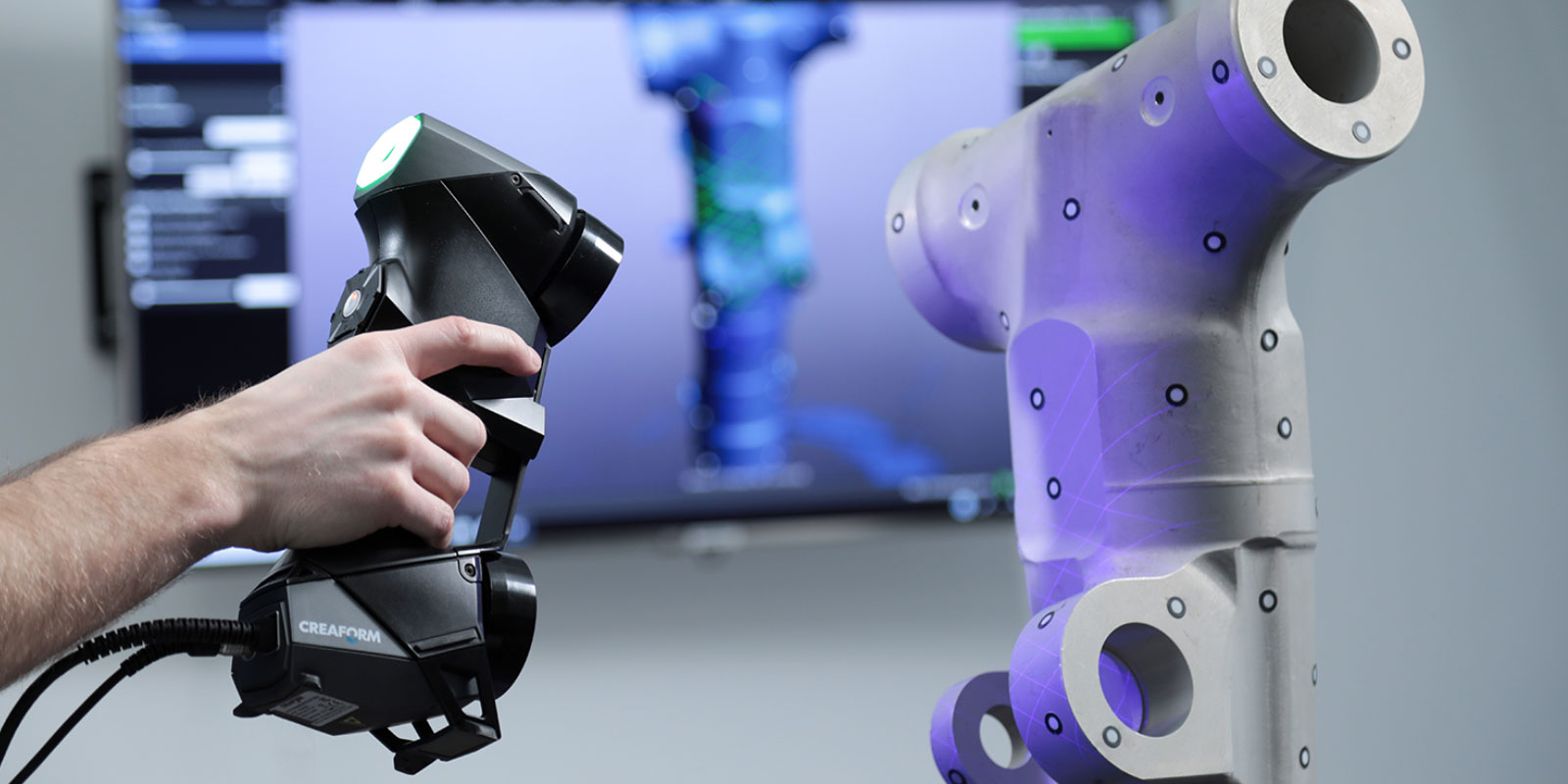

We've modernized the reverse engineering approach for industrial companies. Using metrology-grade 3D scanning, accurate to 0.0009 inches, we scan parts and components of many sizes and material types. With 1.3 million measurements per second, our scanning process reduces reverse engineering measurement time from days to minutes.

Captured and validated on a scanner-connected computer, the part is converted into a 3D mesh. From there, our team reverse engineers the 3D mesh into a feature-based model that can be exported to CAD-based software, such as Solidworks.

Features of 3D Scanning

3D Laser Scanning

3D scanning services modernize the reverse engineering process by instantly creating a 3D mesh for 0.0009+/- inch accuracy.

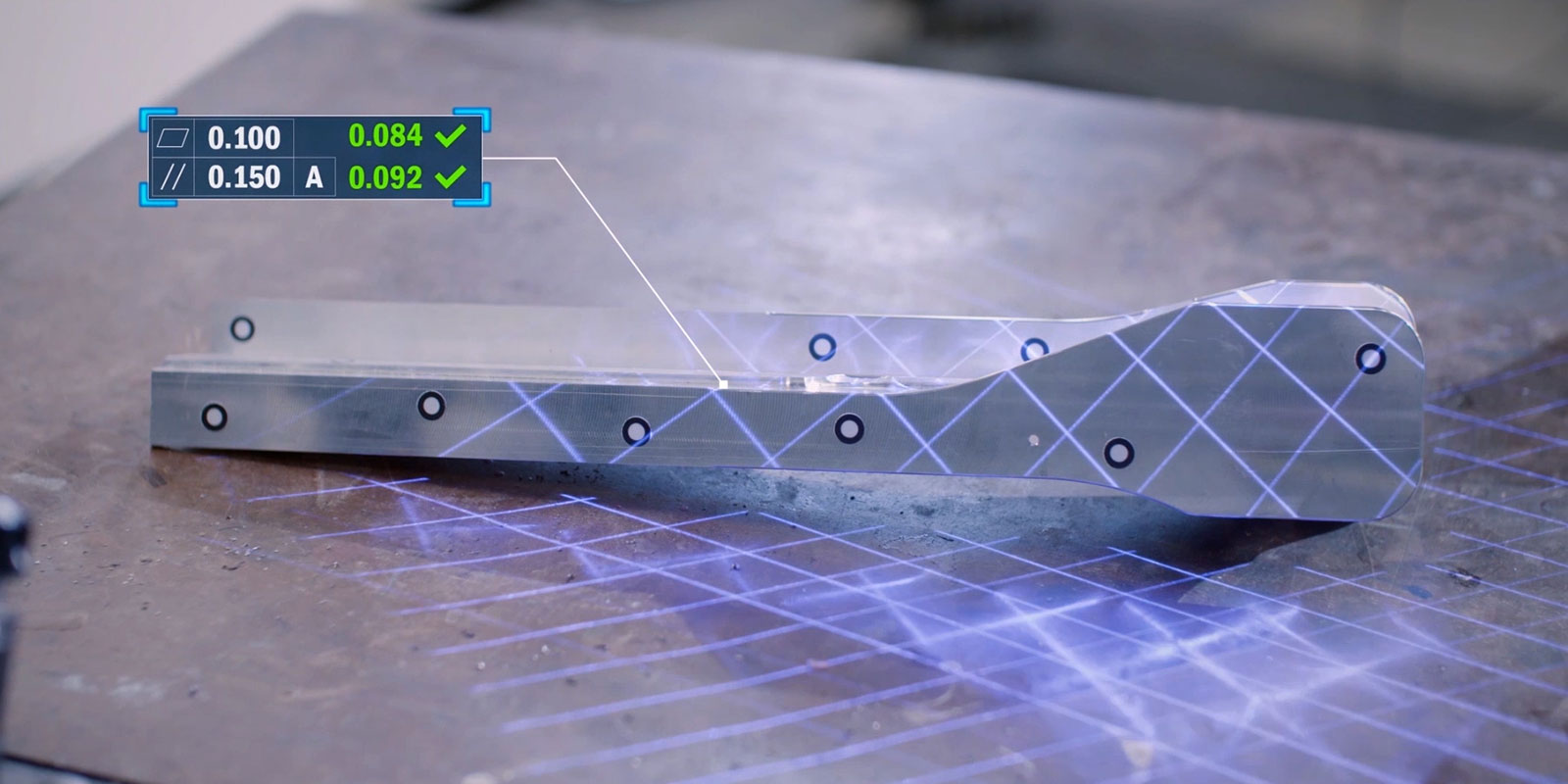

Part Inspection

Professionally trained staff and metrology-grade measuring provide dependable quality control in a fraction of the time traditional process require.

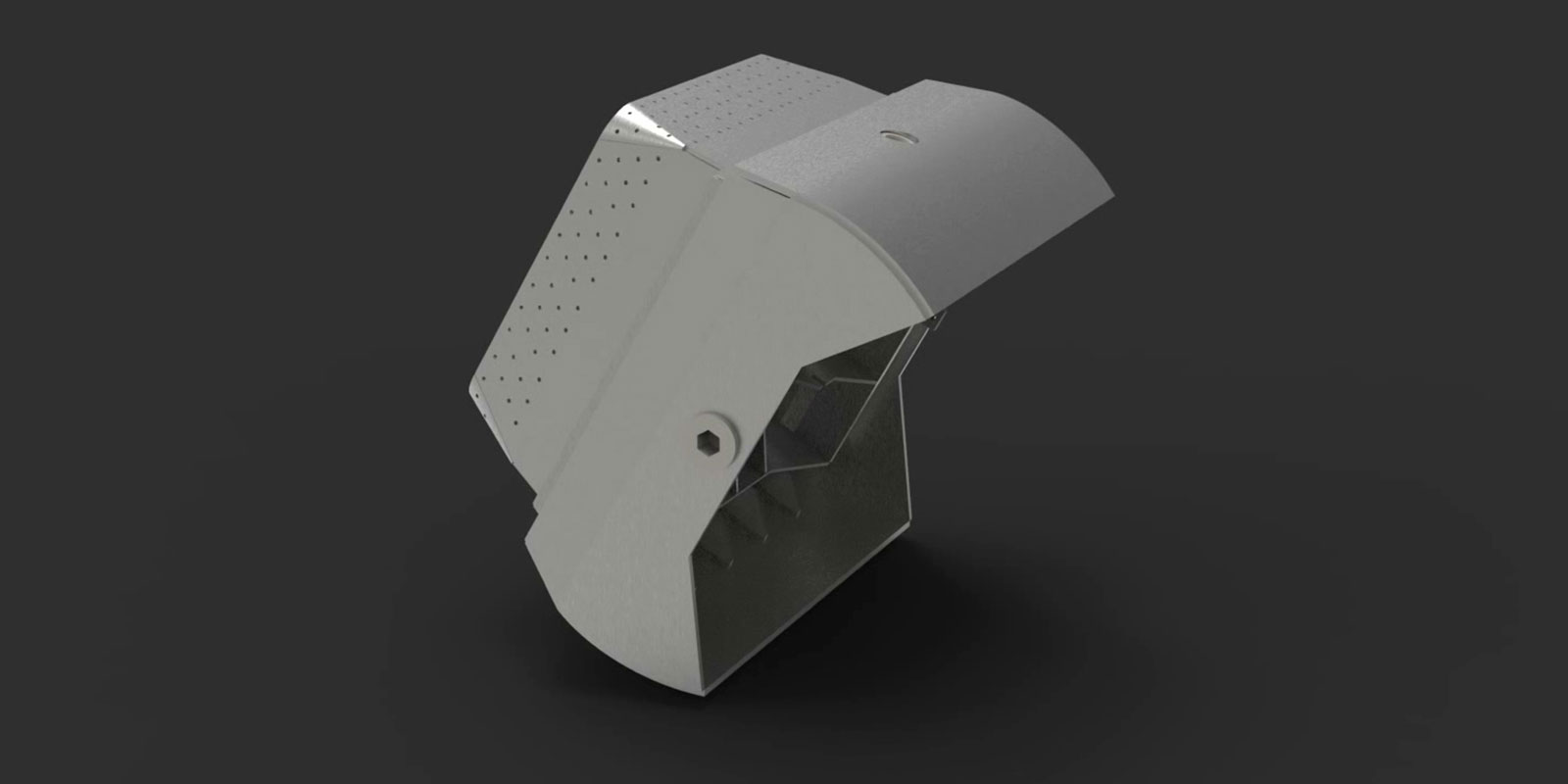

Reverse Engineering

We convert the scanned 3D mesh into feature based models that are imported directly into CAD software, such as Solidworks.

Take the First Step

Get in touch with our engineering team to get the reverse engineering process started.

Reverse Engineering Process

With our modern approach to reverse engineering, we dramatically reduce turnaround time. Customer parts can be scanned and returned quickly to become available for production or inventory. We use the following process to reverse engineer parts:

Identify parts which require reverse engineering. These could be parts where drawings do not exist or parts which belong to an obsolete machine.

Complete 3D Scanning of all components in project scope, in a fraction of the cost of traditional reverse engineering.

Complete reverse engineering process by converting 3D mesh into a feature-based, CAD importable model.

The part can be redesigned by your staff or the R-V in-house engineering team.